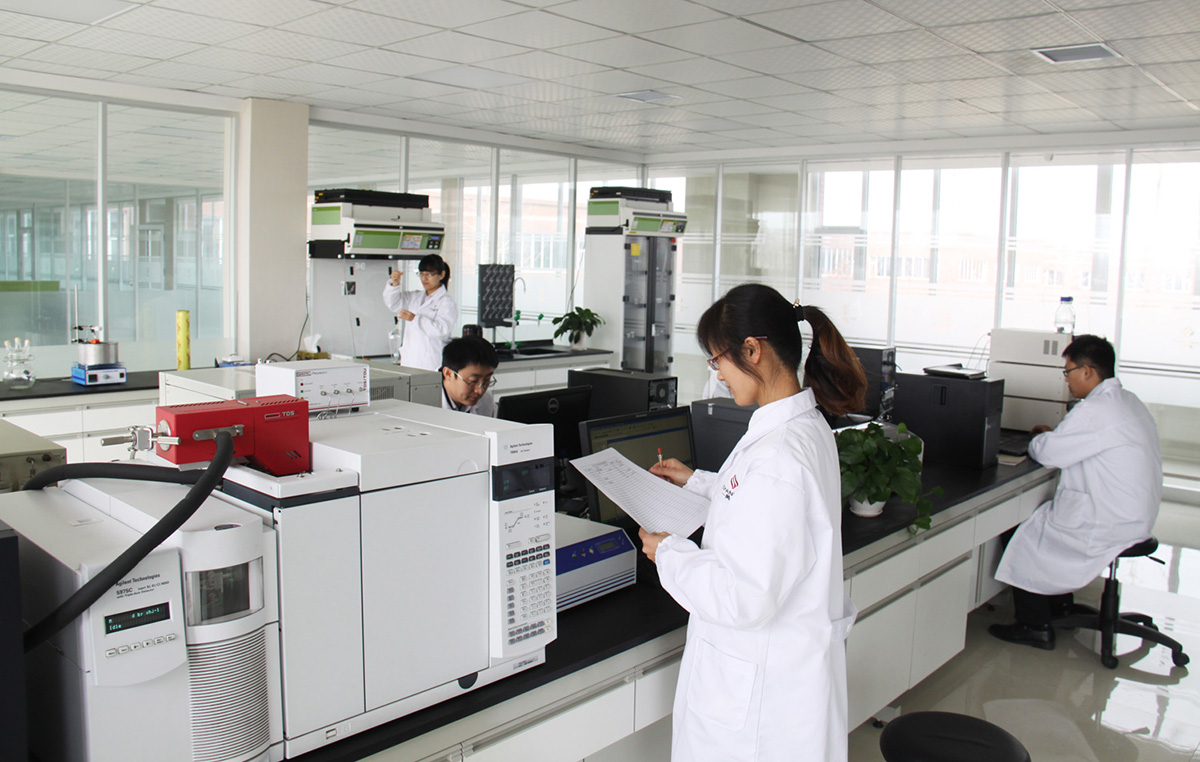

The R & D Department of the Technology Center keeps pace with the market development, keeps abreast of the industry's cutting-edge information, and has a highly capable and skilled team. The professional expertise of the block system, biological enzyme hydrolysis technology, Maillard reaction technology, microcapsule embedding technology, spraying and vacuum drying technology all stand out in the industry. The R & D center has successively introduced the automatic perfumer of Hamilton in Switzerland, the gas chromatography-mass spectrometer (GC-MS) of AGILENT in the United States, the thermal desorption (TDS) in Germany (GERSTEL), Infrared spectrometer (IR), laboratory equipment of IKA in Germany, and ELAB (France) tubeless clean air ventilation equipment. Sophisticated analytical instruments and advanced experimental equipment provide powerful help and support for research and development. The laboratory has also established a professional database of flavors and fragrances.

The basic scientific basis of bioenzymatic hydrolysis technology is that the substance is fully decomposed through the action of enzymes, and various lipases are used to selectively cut the long fat chains in milk fat to generate free fatty acids and release the natural taste in milk fat. substance.

Maillard reaction technology is a common non-enzymatic browning phenomenon, which is widely used in food flavors. This technology will exist in foods such as amino acids, reducing sugars and other premise substances that will produce aromas. After heating reaction under high pressure or normal pressure reflux, different rich flavor substances are produced.

Microcapsule embedding technology refers to the technology of granulating essences wrapped with various natural or synthetic flavor components in the form of tiny core materials by shear emulsification and wrapped in solid wall materials. This technology is to encapsulate the volatile flavor raw materials into non-volatile, and the oxidation and thermal decomposition effects are more slow, so that the flavor and fragrance remain longer.

Spray drying technology is to fully atomize the pre-processed precursor material with aroma components in the drying room, and then in contact with hot air, the water vaporizes quickly to obtain a dry powder essence. This technology can dry solutions or emulsions with fragrance components into powder or granular products, making the fragrance more natural and realistic, with a strong sense of flesh and long-lasting fragrance.

Gas chromatography mass spectrometry

Clean air ventilated kitchen, sample cabinet